In the past three decades, India has become the leading milk producer in the world from the point of facing acute milk shortage. The production level even exceeded 100 million tonnes in 2006, which was possible due to the Operation Flood initiative of the Indian Government from 1970 to 1996. The production and productivity were enhanced due to several welfare initiatives like artificial insemination (AI), veterinary services, improved feed and farmer education. According to a report of the Minister of Fisheries, Animal Husbandry, the dairy industry in India grew at a rate of 6.4 % annually in the past four years. However, animal productivity is 1,806 kg a year, which is lower as compared to the global average of 2,310 kg a year. Besides this, other problems like adulteration and farmers not getting the right price for their products still remain a concern.

In rural India, farmers sell their milk to collection centers and receive the payment based on the presence of FAT in the milk. The local milk analyzer available at collection centers can give incorrect readings or can easily be manipulated, which results in farmers not receiving a fair price for their milk.

Some of the existing challenges in the Indian dairy industry:

- Currently, payment to the farmer is made only on FAT basis. The quality of milk procured may not conform to expected quality standards and could result in increased chilling, transportation and processing cost.

- Problems arise due to the non-cleaning of machines with recommended cleaning solutions, which leads to increased downtime cost and maintenance cost.

- Non-cleaning of machines also leads to variability in milk analyzer, resulting in an erratic reading of FAT and SNF. The machine stops working due to which a number of days are wasted and manual entries have to be made.

- Manual calibration of milk testing equipment opens up the possibility of malpractices, without any historical log of actual calibration.

- Lack of historical data on milk testing machine on-off data, milk procurement, milk composition, machine cleaning data, calibration, etc. gives an indication of no predictive maintenance.

- Farmers lack assurance whether the machine is providing accurate milk parameters since the calibration is done manually.

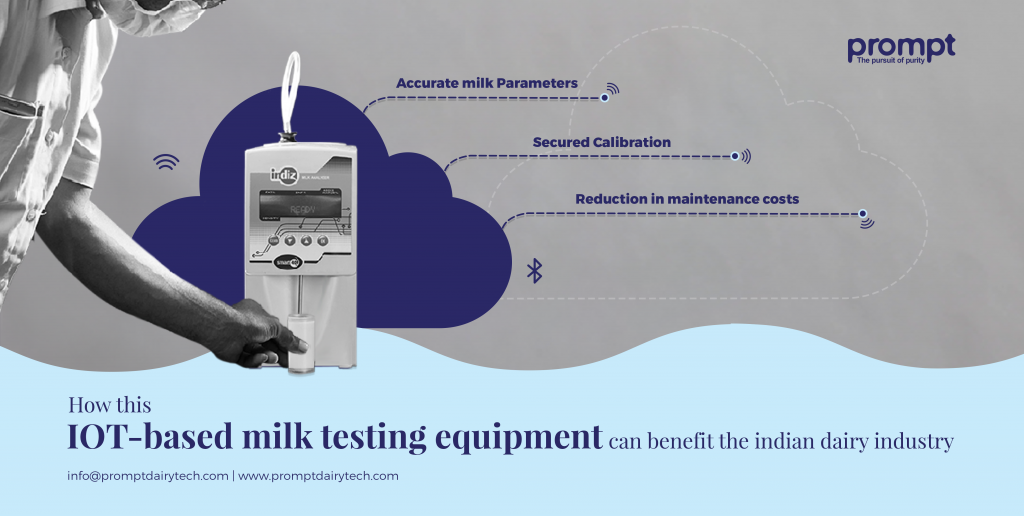

To overcome these challenges, Prompt Equipments have designed an innovative Advanced Smart Milk Analyzer with Bluetooth and cloud connectivity.

The smart milk analyzer is based on the IoT (Internet of Things) technology and due to online calibration, farmers can be assured that the machine displays accurate milk parameters and is free from any adjustments. The online calibration prevents human interference and farmers will always get the right price for their milk.

Some of the features of Smart Milk Analyzer are:

Accurate milk Parameters: Get the percentage of FAT, SNF and water proportion, besides the density in single testing.

Easy Operations: The milk analyzer doesn’t require much effort in getting acquainted with its operation, cleaning and calibration.

Rugged: Despite being designed and built on a lightweight framework, the milk analyzer is resilient to any weather conditions and attrition.

Cost-Effective: The milk fat testing equipment consumes little power for its operation which means more productivity without consuming much power.

Secured Calibration: The mobile application provides a highly secure calibration, which can only be accessed by the authorized person.

Prevent Maintenance: External Bluetooth device is given along the machine. It can be attached with the mobile app, which manages the calibration.

Log management: The machine stores the cleaning and calibration logs through which verification and analysis of all the events made in the analyzer can be done. Also, it includes the storage for the samples’ history.

Preventive Health Check-up: The milk analyzer does not operate until critical self-tests are done. This leads to regular cleaning of machines, reduced downtime cost and accurate operations of the machine.

How these features will overcome some of the existing challenges in the dairy industry.

- Payout to farmers can be optimized by linking with the tested SNF in a real-time environment.

- With improved milk quality, the quality of value-added dairy products will subsequently improve

- Elimination of manual calibration results in – similar FAT/SNF reading at society and dairy-level – which eliminates any scope of malpractices and ensures optimum milk quality.

- Availability of data allows the generation of analytical reports and gives actionable insights for decision-making.

- Variability in SNF can be controlled.

- Reduction in maintenance costs and downtime.

Through this smart and innovative milk testing equipment, Prompt Equipments has stepped up to solve some of the existing challenges of the Indian dairy industry. This machine is based on the IoT technology that is revolutionary and secure. We make the right use of technology and leverage it for the benefit of society-at-large.