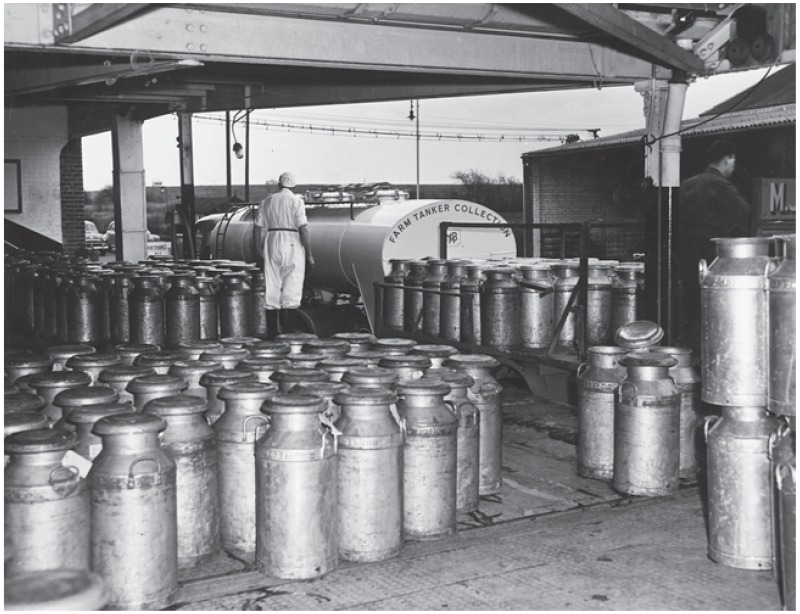

India is the biggest milk producer in the world where small dairy farms play a major role in the production. However, the quality of milk is not of desired levels because Indian dairy farmers – one of the factors is lack of cooling infrastructure at the village level. Milk needs to be chilled to lower temperatures in order to arrest the bacterial growth and thus prevent the milk from getting spoiled. Milk chilling facilities at the source are a vital element of maintaining the quality of milk and ensuring better profit for farmers.

In a developing country like India, the facility is still not in wide use. This is very less compared to developed countries where the duration is 7-10 days. Let us understand the current situation in India.

What is the current situation in rural India?

Farmers in rural India have to travel for around 2-3 hours to reach a milk chilling facility. The milk would then get chilled in a Bulk Milk Chiller and transported to the processing plant for further action. During summer, most Indian rural areas experience scorching temperatures, which are not ideal for maintaining the quality of milk. This leads to the quality of milk deteriorating when it gets taken to a chilling facility.

Dairy farmers often have to race against the time to get the milk chilled within four hours to prevent bacterial growth. Availability of electricity is another problem as there can often be power cuts. Additionally, the usage of diesel generators is not an ideal proposition because of economic and environmental factors. All these factors necessitate the use of an eco-friendly instant milk chiller right in the dairy farm.

What are the advantages of chilling milk instantly?

Milk is an important commodity that is an essential source of nutrition in developing countries. However, unless it gets maintained and stored well, it can get spoiled quickly. Bacteria like Lactobacillus is naturally present in the milk, which spoils the quality of milk if not controlled. If the milk gets chilled within four hours from the time it gets produced, we can reduce the chances of spoilage. It requires an instant milk chiller and regular power supply to ensure that the facility can get used with no disturbance.

Dairy farmers get the returns on their milk based on its quality. So, even if they deliver a good quantity of milk, they might not get the right price if the quality is not good. This significantly affects the income of dairy farmers. When they have the right equipment like a milk chiller, they can control the quality of milk and get better returns for increased profits.

How to choose the best milk chilling equipment?

There are several milk chilling equipments available in the market. It can be quite overwhelming to choose the best one for your dairy farm. However, we list some ideal qualities you must consider when buying an instant milk chiller.

- Economically priced to ensure a good ROI (return on investment).

- Easy to operate with low maintenance cost.

- It must have scalability with a compact design.

- It must have the ability to operate in areas with limited power supply

- It would be a bonus if it can generate hot water from heat recovery, which is suitable for cattle sanitisation.

Final Thoughts

Chilling milk instantly at the source has many benefits. It maintains the quality of milk and also ensures that farmers get the right price for their milk production. It is beneficial in the long run and important for all dairy farms, irrespective of their size.

If you are looking for a service provider, you need a seasoned technology provider that understands the industry well. Prompt Equipment’s patented technology MilkoChill is a milk chiller that can help you chill milk instantly right at your doorstep. To know more details, please contact us today.