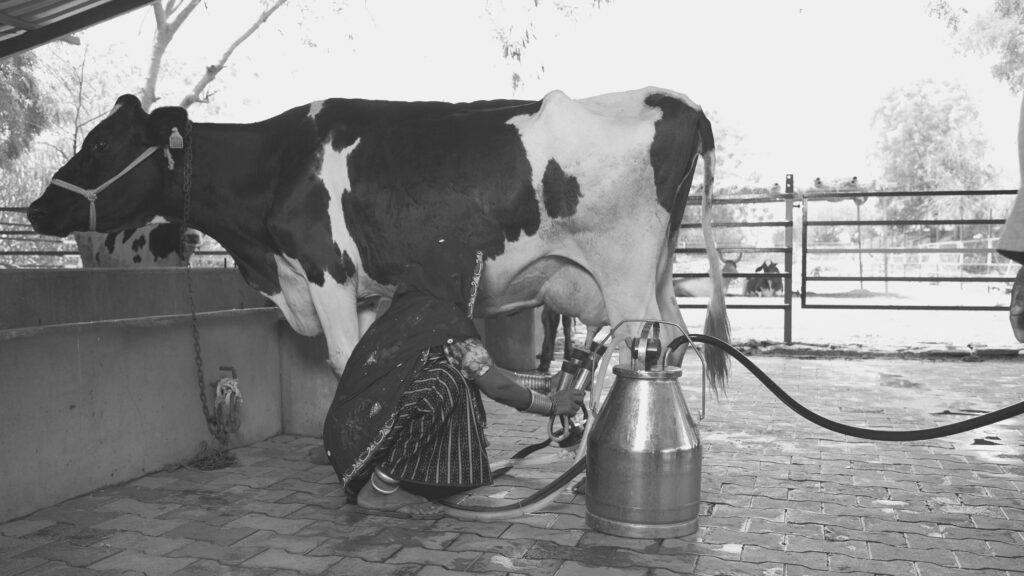

Managing milk is one of the most critical and pivotal exercises in the milk production chain. The milking Machine is one of a kind, as it is one of the few machines that interact with the cattle consistently. It is essential that these machines get installed properly, have regular maintenance, and used appropriately in the dairy farms. In this article, we will explore how milking machines are essential in modern dairy farming.

How do milking machines work?

The milking machines of the modern-day are an excellent fit for milking cows and buffalo. They do not cause any harm to the udder. The working guideline of the equipment is to mimic the suckling of the calf. The cattle milking machine performs two essential activities. At first, it uses a vacuum to create pressure, allowing milk to come out in a container. Next, it will massage the teat, which avoid the blockage of blood.

The milking unit is a part of the equipment, which aids in removing milk from an udder. It comprises a hook, four teatcups, milk tube, throb tube, and a pulsator. The hook is a gathering that interfaces the pulse tubes and milk tubes from the teatcups to the longer pulse and milk tube. Paws are usually made of hardened steel or plastic or both. Teatcups have an unbending external shell that holds a delicate inward liner. Simple areas in the shell may permit the view of liner breakdown and milk stream.

Why milking machines are important in a dairy farm?

Milking equipment work in a manner that is not the same as calf nursing or manual milking. A constant vacuum gets applied inside the delicate liner to knead milk from the teat by making a distinction in pressure across the teat trench. Vacuum additionally helps keep the machine connected to the bovine. The vacuum applied to the teat causes blockage of tissues. Barometric air gets transferred into the pulsation chamber once every second to allow the liner to fall around the teat’s end part. It also eases blockage in the tissue. The proportion of the time that the liner is open and shut is known as the pulsation proportion.

The four surges of milk from the teatcups generally get consolidated in the hook and shipped to the milk line or the collection area. Milk then gets shipped in buckets or with a mix of wind stream and pump to a focal stockpiling tank. Milk gets refrigerated on the ranch either by going through a heat exchanger or in the tank.

As all these activities are automated so the dairy farmer need not have to worry about anything. Milking machines can enable them to concentrate better on other aspects of growing their dairy business.

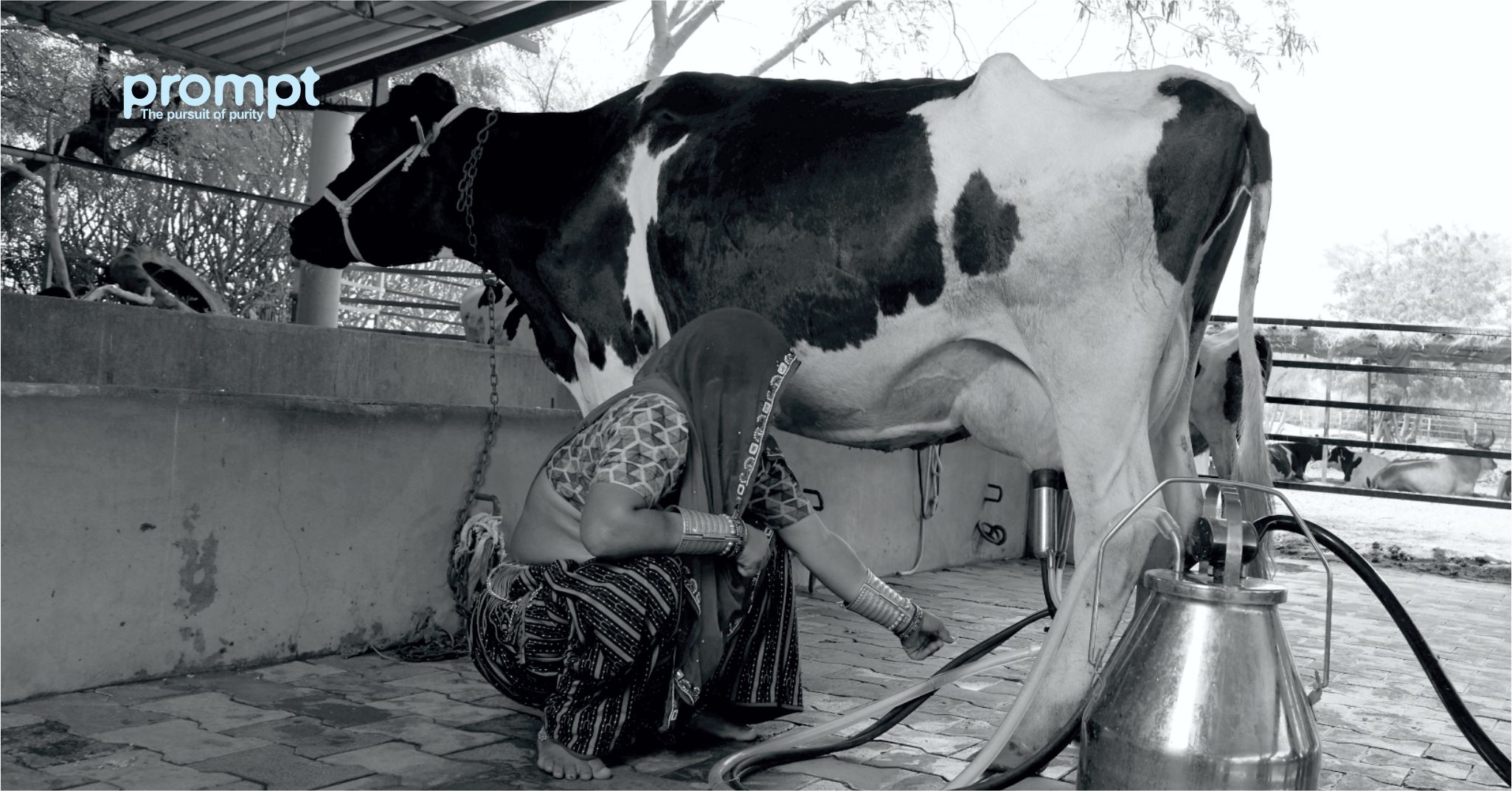

Milkeasy Milking Machine for contamination prevention

Prompt has introduced the MilkEasy Milking Machine to help dairy farmers guard the milk and keep it safe from contamination. When contamination gets eliminated, there can be minimum bacterial count. As it is enclosed and sealed, the milking machine doesn’t permit any contamination of hay, dust, or any other thing that stick to hands while milking cows manually.

Bottom line

Automatic Milking machines assume a significant role in dairy farming. These machines ease your work as you need not bother with any manual labourer to milk the cows and other animals at your dairy farm. You need to install, operate and maintain them accurately with the goal that they will give you benefits for many years in the future. To know more about how Milkeasy Milking Machine can help you get better profits in your dairy farm business, contact us today.