WORLD’S FIRST AI-POWERED,

PATENTED AND COST-EFFECTIVE CRATE

MANAGEMENT SYSTEM

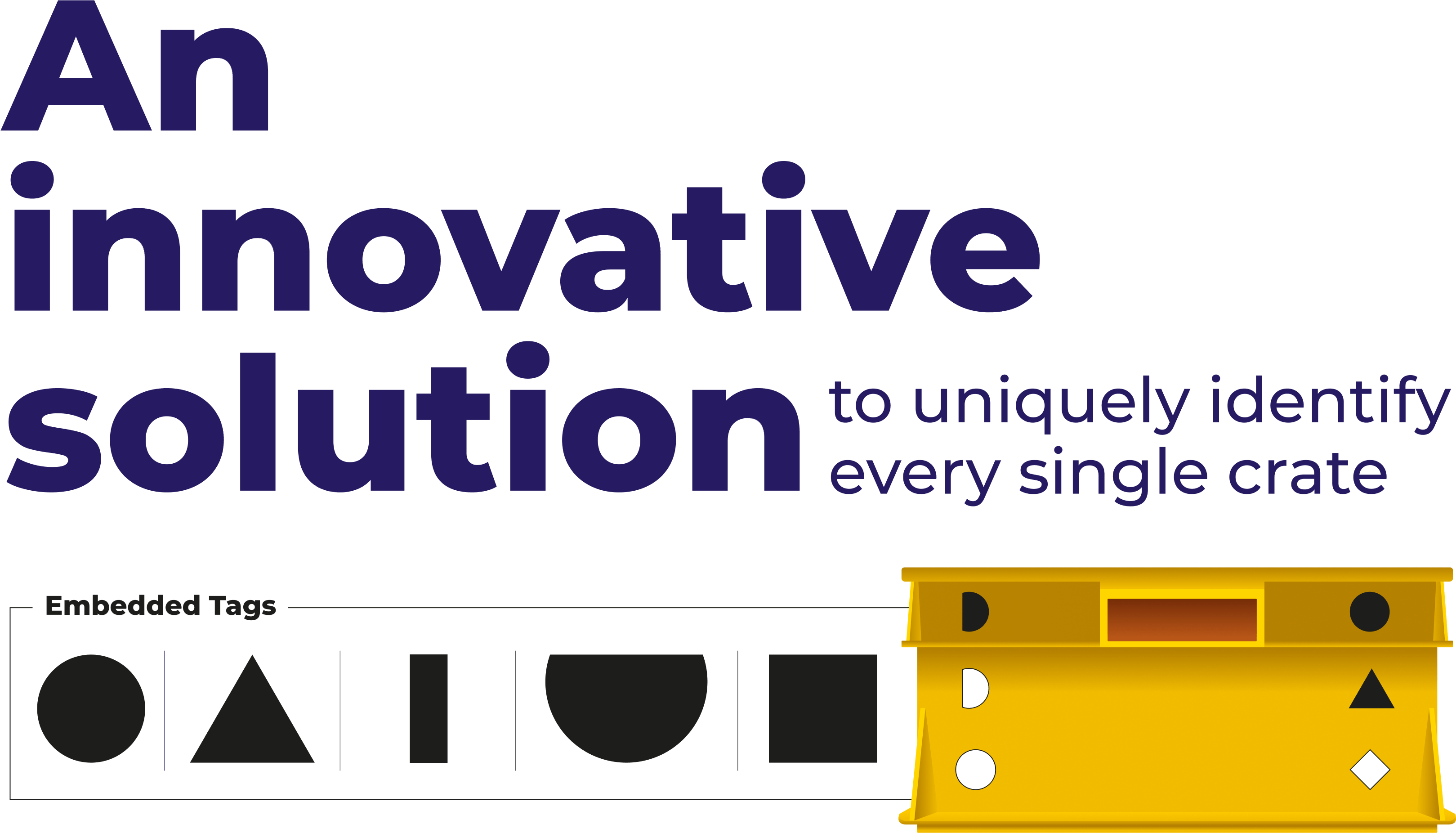

- Crates are embedded with unique, washable, non-removable, lye, acid and heat tolerant tags

of various shapes. - Millions of unique tag combinations are possible for dairies to identify crates.

- An accurate and cost-effective solution to identify the crates.

- Product information can be interlinked by scanning the pack colour to determine the type and

count of SKUs carried by each crate.

Process innovation that improves efficiency

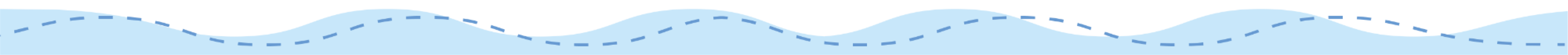

Prompt TrackSure at the Dairy Processing Plant

Without disrupting the process, two industrial cameras on the crate conveyor belt capture images of each crate to be transferred to cold storage.

These cameras capture:

- Unique ID of crates

- SKU of product variant

- Total number of crates

- Product variant in crates by its colour

- Count of product variant in the crates

- Timestamp

Optionally, Checkweigher can be installed on the crate conveyor belt to monitor the

weight of each crate.

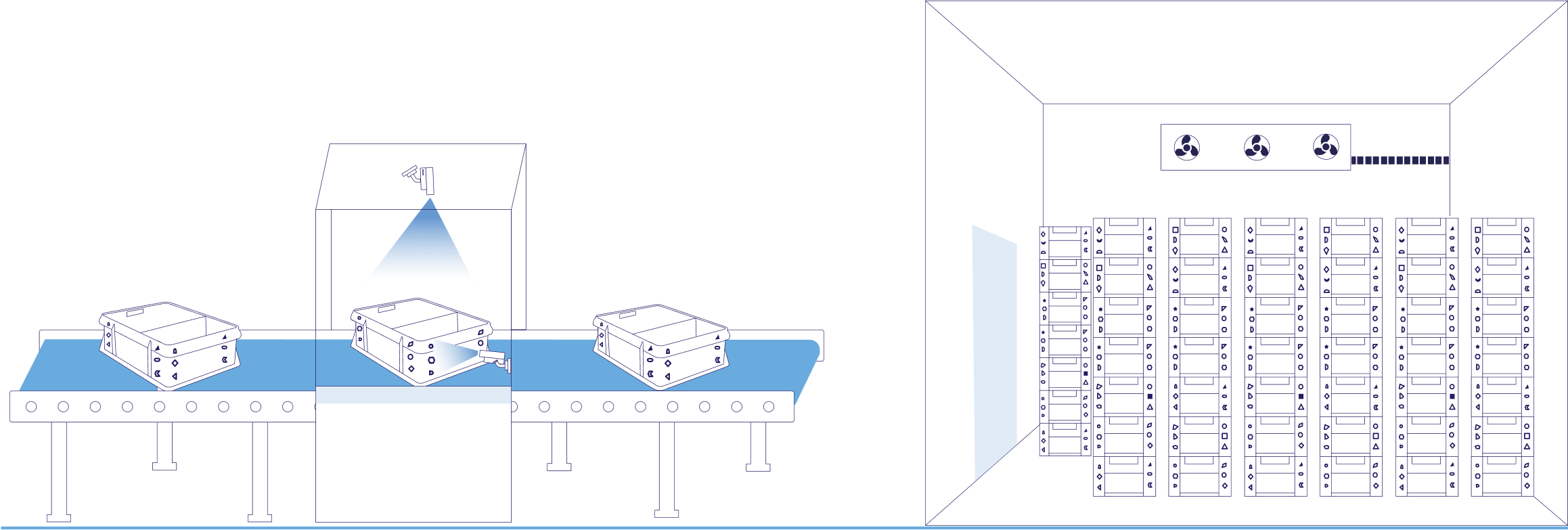

Prompt TRACKSURE at Dispatch Dock

Prompt TRACKSURE Mobile App, which captures:

- Unique ID of crates

- Total number of crates

- Driver and vehicle details

- Geo-location and timestamp

Prompt TRACKSURE application integrates the above information with the details captured in packaging section such as crate ID, product variant, quantity and number of crates.

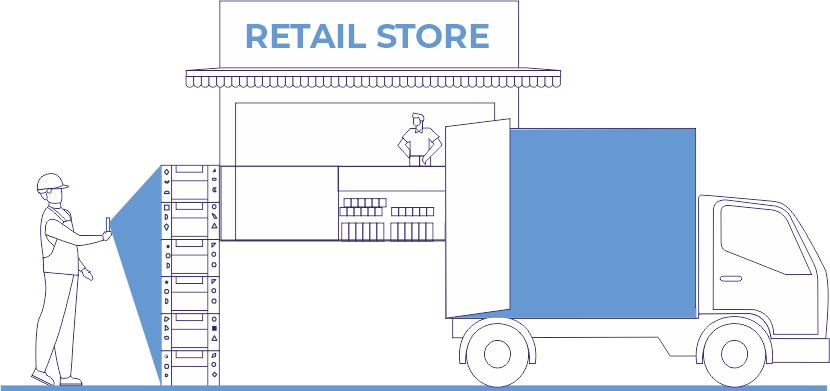

Prompt TRACKSURE at Retail

At the retail store, the truck driver scans the stacks of crates being unloaded from

the truck using Prompt TRACKSURE Mobile App. While loading the empty crates, the

truck driver scans the stacks being returned by retailer, thus capturing the

following data:

- Unique ID of crates

- Total number of crates

- Geo-location and timestamp

This helps identify the number of retailers in a particular geo-location, along with the

consumption and demand patterns of different products.

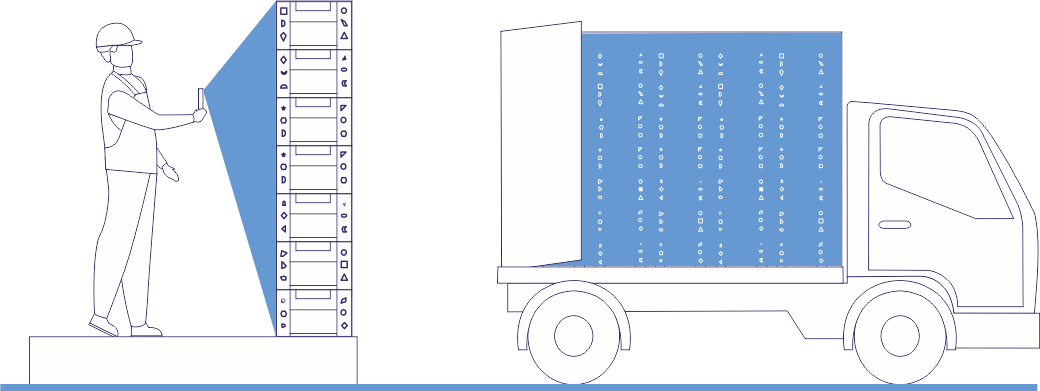

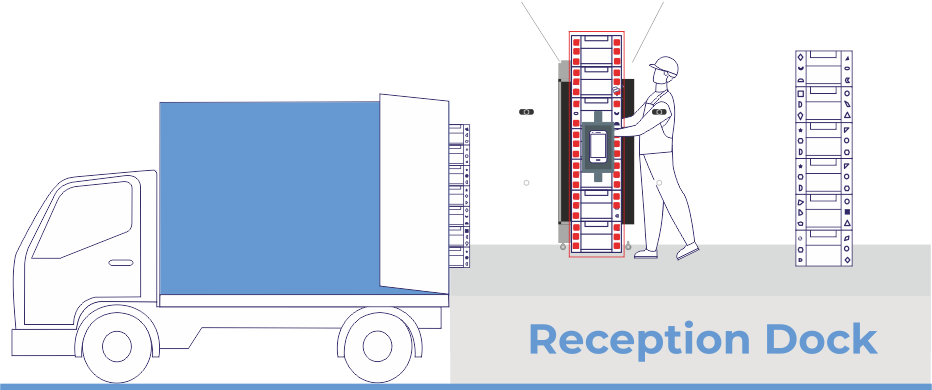

Prompt TRACKSURE at Reception Dock

The app scans the stacks the stack of crates from a returned vehicle will be scanned by Prompt TRACKSURE

Mobile App on a smartphone, mounted on stainless steel stand with black curtain

frame on the opposite side. The app scans the stacks in real time while unloading capturing the following data:

- Unique ID of crates

- Total number of crates

- Which driver returned empty crates from which retail location

- Geo-location and timestamp

Prompt TRACKSURE provides complete overview of crate movement, identifies missing crates

based on unique ID and generates alerts.

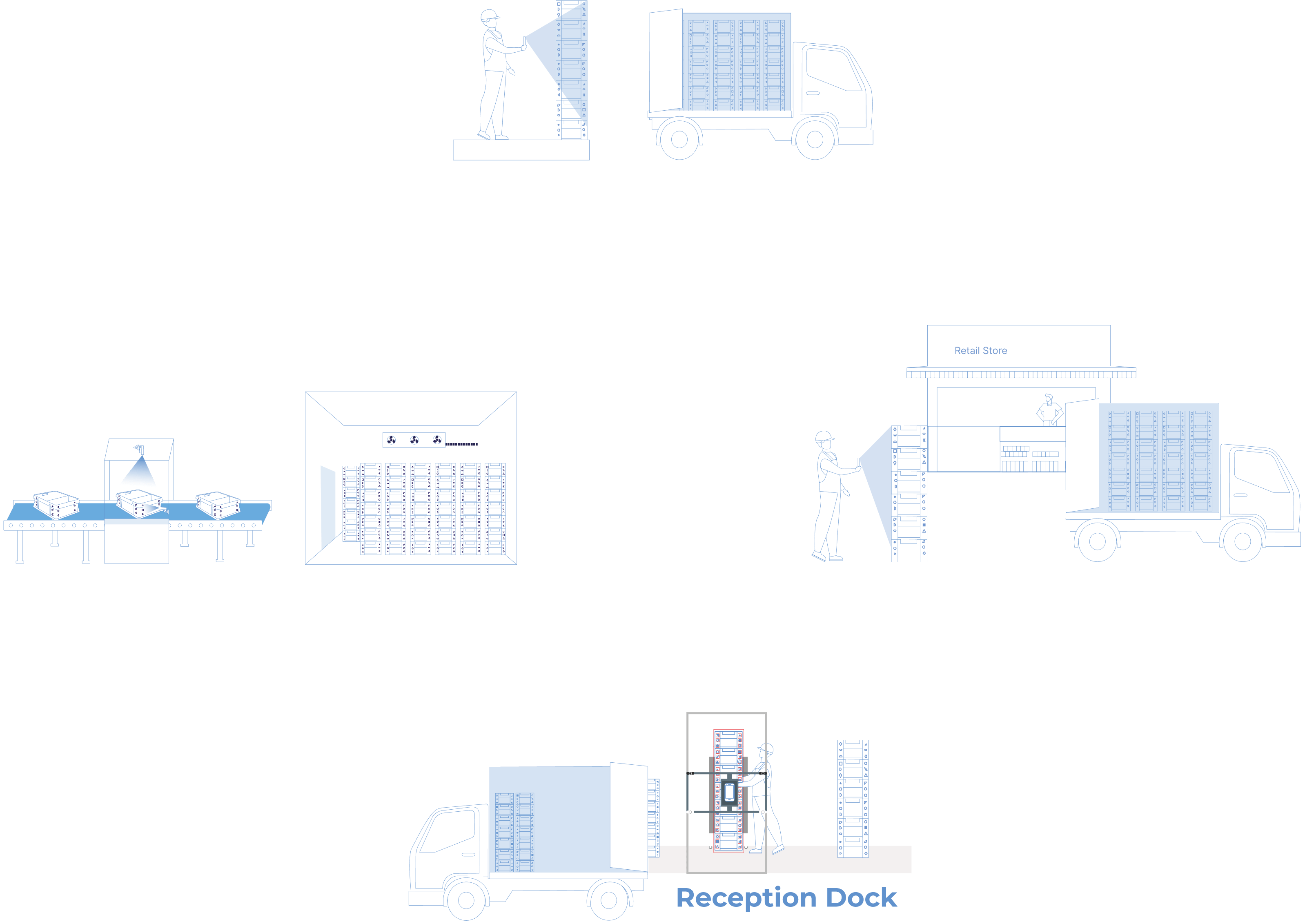

A quick glance at the new crate life-cycle with Prompt TRACKSURE

01

DAIRY PROCESSING PLANT

Crates embedded with unique IDs scanned with industrial camera to identify

and count products before being stored in cold storage

02 DISPATCH DOCK

Scan the crates with Prompt TRACKSURE mobile app while loading it for

dispatch

03 UNLOAD/LOAD AT RETAIL

Scan the crates with Prompt TRACKSURE mobile app during unloading and

loading

04 RECEPTION DOCK

Empty crates being received at the dairy scanned by Prompt TRACKSURE mobile

app

Components of Prompt TRACKSURE

Why choose Prompt TRACKSURE??

- Effective inventory management

- Easy integration with CRM and IT systems

- Real time monitoring

- Data insights for better decision making

- Reduced labour cost

- Cost effective solution

- Increase efficiency

- Improve accuracy

Download Brochure

Get in touch

It will only take a minute

FAQs on Crate Management System

A crate management system is a software or technology solution that helps organizations effectively track, manage, and control the movement and inventory of crates.

A crate management system offers several benefits, including improved inventory accuracy, efficient crate utilization, streamlined operations, reduced crate loss or theft, enhanced traceability, and increased productivity.

The entire solution is very cost effective and pays for itself in a very short period of time. The exact cost of the solution will depend upon the number of fixed terminals using industrial camera setup, no of mobile based users, number of crates, no of different SKU in scope etc. Please share your requirements with us to help you serve better.

A crate management system enables organizations to maintain accurate and up-to-date inventory records. It tracks the movement of crates, records their contents, and alerts users when crates need to be returned, or relocated, ensuring optimal inventory levels and minimizing stockouts or overstock situations.

Yes, crate management systems are adaptable and can be used across various industries that rely on the movement and storage of crates, such as manufacturing, logistics, retail, e-commerce, food and beverage, healthcare, and more.