AN AI POWERED DIGITAL LEAP IN COMPLETE TRACKING AND MONITORING OF CARTON BOX MOVEMENT

Meet these challenges in carton box traceability

- Getting accurate traceability data in industries with high production speeds.

- Integrating traceability system with existing production systems

- Apprehensions about barcode or RFID readability

- Losses from theft, pilferage or improper packing

ACCURATE & INTELLIGENT: A Real-time Track & Trace System Powered by AI technology

- Automates the entire process of

reading product information and

generating and printing QR code - Reduces overheads significantly

- Avoids pilferage and other losses

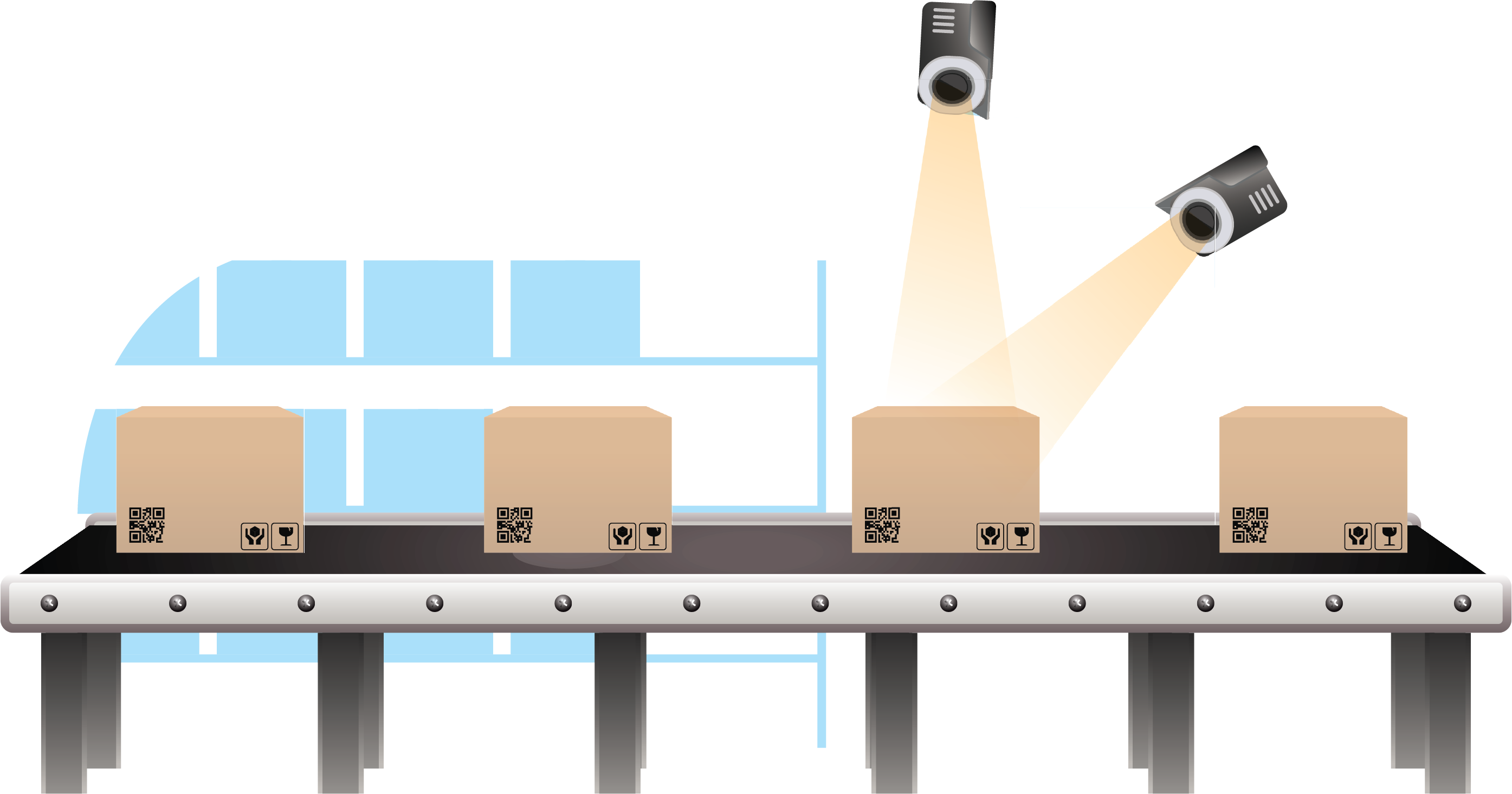

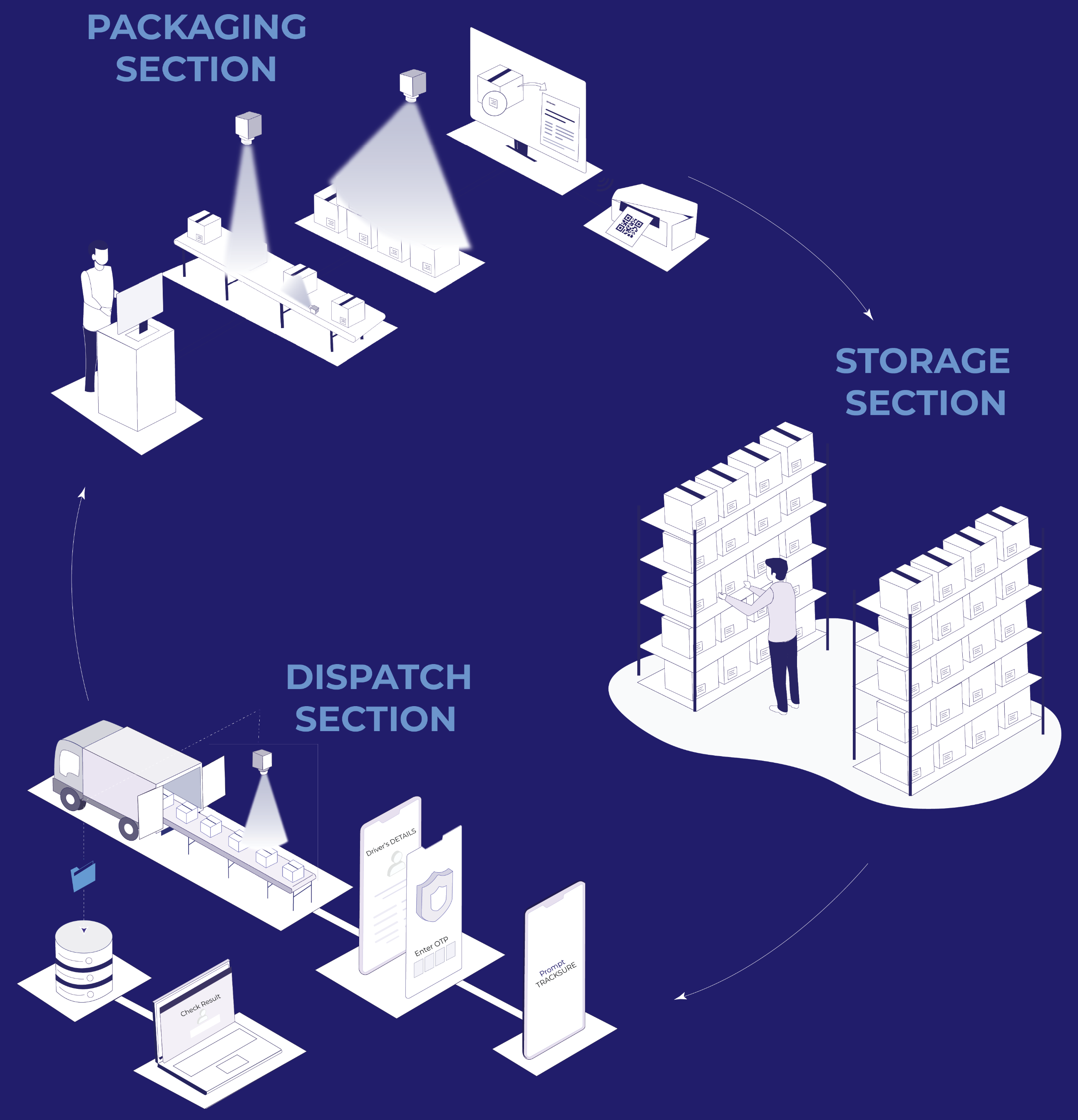

PACKAGING SECTION

Providing real-time update of stock transferred

- Extracting the following information using

Industrial cameras that are fixed on packing

conveyor for capturing the images of each

box having primary packs. - SKU-wise weighing records and rejecting with

alarms if needed - Timestamp

- Reading the product information printed on

boxes for variant name, SKU details,

SAP Code etc. - Mapping the product along with weight data

and giving input to online QR printer for

printing along with pre-filled information

such as manufacturing date, expiry date

and batch no.

qr code

Unique 8-digit alphanumeric no. with 1 digit fixed

QR code would contain:

- Unique ID

- Batch no

- Date of manufacturing

- Date of expiry

- SKU Name

- Weight information

- Printing QR on CFC boxes

- Reading the QR before entering into warehouse

- Alert will be generated for any deviation in count between production and warehouse scanning

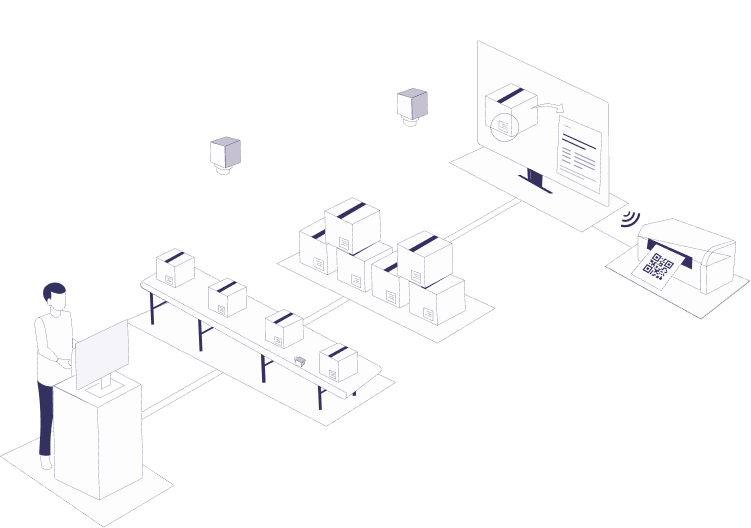

STORAGE SECTION

Getting real-time update of stock count and carton transfer details

- Initiating session from desktop application

- Capturing QR for each carton on conveyor, at

the entrance of storage - Difference in count, if any will be notified

through alert mechanism - Checking result on Web Portal and Mobile app

using credentials

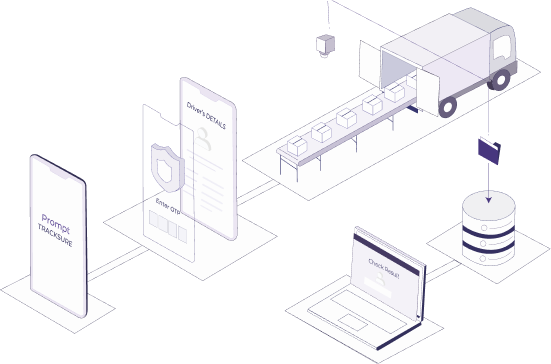

DISPATCH SECTION

Giving real-time updates of stock count and carton uploading details

- Initiating process with TrackSure app

- Authenticating driver’s detail, using OTP

- Scanning of QR code using industrial camera

or QR reader while loading the vehicle - Mapping delivery challan- SKU wise

- Generating verification report- SKU wise

- Stop capturing of data and submitting

information to server - Check results on Web Portal and Mobile app

or in scan history Portal and Mobile app

using credentials

A quick glance at the carton box movement with Prompt TRACKSURE

Components of Prompt TRACKSURE

Hardware:

Industrial camera,

lights, sensor

Industrial camera,

lights, sensor

QR Printer

Online checkweigher with rejector

Web portal and

Mobile app

Mobile app